Glass Adhesives

Bonding glass to glass, glass to metal or glass to polycarbonates can be challenging – not so with Panacol’s glass adhesives. As glass is transparent or translucent, UV curable adhesives are the best choice for ensuring a reliable, permanent, and invisible bond.

The majority of Panacol’s glass adhesives will cure under UV light or visible light. Adhesives that were specially adapted to cure under visible light are the perfect solution to bond UV blocked glass (such as VSG). Both our UV and visible light curable adhesives for glass bonding can be used with either monochromatic LED light sources or broad spectrum UV discharge lamps.

Curing in fractions of a second, our Vitralit® glass adhesives reduce assembly time and lower total process costs. These adhesives ensure high strength bonding of glass to glass, glass to metal (typically to steel or aluminium), or glass to other dissimilar substrates, including polycarbonate and acrylic. These adhesives are ideal for flat glass, float glass, tempered glass, and most other glass compositions.

Panacol’s Vitralit® glass adhesives are single component and solvent-free, easy to dispense and to handle. Many are available in multiple viscosity ranges, from water-like wicking grades to highly filled thixotropic gels. Vitralit® glass adhesives can be specifically matched to the unique requirements of the application. Selections can be made based on the adhesive’s optical clarity, refractive index, or resistance to environmental stresses including temperature and humidity. To minimize movement and stress in optics, Vitralit® adhesives are available with low CTE (coefficient of thermal expansion), low shrink during cure, and high Tg. For medical applications, Panacol possesses a variety of medical grade adhesives that are biocompatible and are resistant to common sterilization processes.

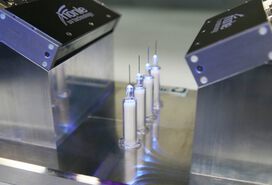

Panacol’s glass adhesives are used to bond optical assemblies, mirrors, hardware for glass shower enclosures, display cases, outdoor lighting, decorative bevels or bonding of electronic displays. Medical applications include the bonding of metal cannulae into glass syringes.

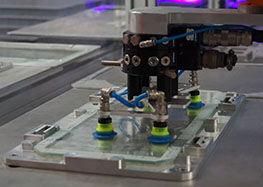

Fast curing Vitralit® glass adhesives are used in automated production lines for bonding glass panes.

Below is a selection of light curable glass adhesives and glass bonding solutions. Please open one of the links below to view the technical data sheet.

Glass Adhesives for Optoelectronics

| Adhesive | Viscosity [mPas] | Base | Curing* | Properties | Substrates |

|---|---|---|---|---|---|

| Vitralit® 1505 | 250-400 (LVT, 25 °C, Sp.3/30rpm) | epoxy | UV |

Very high glass transition temperature excellent chemical resistance low attenuation |

Glass bonding |

| Vitralit® 1517 | 10,000-20,000 | epoxy |

UV secondary heat cure |

low shrinkage very high Tg low heat expansion |

Glass bonding |

| Vitralit® 1527 | 600-1,250 | epoxy | UV |

Very high tg low attenuation high transmission high chemical resistance nanostructured fillers |

Glass bonding |

| Vitralit® 1528 | 350-850 (LVT, 25 °C, Sp. 3/60 rpm) | epoxy |

UV secondary heat cure |

low attenuation very high Tg |

Glass bonding |

Flexible Glass Adhesives

| Adhesive | Viscosity [mPas] | Base | Curing* | Properties | Substrates |

|---|---|---|---|---|---|

| Vitralit® 4731 | 900-1,500 (LVT, 25°C, Sp. 3/30 rpm) | acrylate |

UV VIS |

Dry surface after curing, biocompatible: certified to USP Class VI and ISO 10993-5 standards |

Bonding PC /Makrolon, hard-PVC, PET, ABS, SAN, PMMA (Plexiglas®, acrylic glass) Bonding glass, steel, stainless steel, aluminium, brass |

| Vitralit® 4731 VT | 4,000-8,000 | acrylate |

UV VIS |

dry surface after curing flexible and tear-proof excellent adhesion to many plastics |

bonding PC (Makrolon), hard-PVC, PET, ABS, SAN, PMMA (Plexiglas®, acrylic glass) joining glass and plastics joining metals to plastics |

| Vitralit® VBB-1 | 1,000-1,500 | acrylate |

UV VIS |

Elastic high peel strength optically clear very flexible suitable for potting |

Bonding PC (Polycarbonate), PMMA Bonding plastics to glass |

| Vitralit® VBB 1 Gel | 12,000-30,000 | acrylate |

UV VIS |

Elastic high peel strength optically clear very flexible stable gel |

Bonding PC (Polycarbonate), PMMA Bonding plastics to glass |

| Vitralit® VBB-2N LV | 10-100 | acrylate |

UV VIS |

Flexible perfect solution for bonding large surfaces high peel strength |

Plastics and rubber bonding suitable for bonding PMMA, PC, hard-PVC, PET, ABS, SAN, FR4, PBT in combination with glass and metals |

| Vitralit® VBB-N | 50-150 | acrylate |

UV VIS |

Transparent elastic high peel strength |

Bonding PC (Makrolon) PMMA (Plexiglas®, acrylic glass) Bonding plastics to glass |

| Vitralit® VBB-N2 SV | 300-500 | acrylate |

UV VIS |

very elastic high peel strength suitable for large-area bonding |

Glass adhesives for bonding with metals, glass, ceramics

| Adhesive | Viscosity [mPas] | Base | Curing* | Properties | Substrates |

|---|---|---|---|---|---|

| Vitralit® 6108 | 600-900 | acrylate |

UV VIS secondary heat cure |

non-yellowing excellent flow properties certified to USP Class VI and ISO 10933-5 standards |

Bonding hard-PVC, ABS, SAN, Glass, steel, aluminium, brass, stainless steel |

| Vitralit® 6108 T | 3,000-6,000 | acrylate |

UV VIS secondary heat cure |

non-yellowing excellent gap-filling certified to USP Class VI standards shear thinning |

Bonding hard-PVC, ABS, SAN, Glass, steel, stainless steel, brass, aluminium |

| Vitralit® 6125 | 4,000-6,000 (LVT 25°C, Sp. 4/30 rpm) | acrylate |

UV secondary heat cure |

excellent adhesion to stone, glass, metals and thermoplastics medium viscosity |

|

| Vitralit® 6127 | 20-100 (LVT 25°C, Sp. 2/60 rpm) | acrylate |

UV secondary heat cure |

high purity specially formulated for bonding glass |

|

| Vitralit® 6128 | 800-1,200 | acrylate |

UV secondary heat cure |

very high adhesion to stone, glass, metals and thermoplastics high temperature resistance |

|

| Vitralit® 6128 VT | 3,000-6,000 (Rheometer, 25°C, 10s^-1) | acrylate |

UV secondary heat cure |

contains chemical activator high temperature resistance high viscosity excellent adhesion to stone, glass, metals and thermoplastics |

|

| Vitralit® 6133 | 600-1,000 (LVT 25°C, Sp. 3/30 rpm) | acrylate |

UV VIS |

High strength and impact resistance very high adhesion to glass metals and anodized aluminium transparent |

General glass adhesives

| Adhesive | Viscosity [mPas] | Base | Curing* | Properties | Substrates |

|---|---|---|---|---|---|

| Vitralit® 1605 | 200-400 (LVT, 25°C, Sp. 2/30 rpm) | epoxy |

UV secondary heat cure |

low shrinkage low heat expansion very high tg excellent chemical resistance certified to ISO 10993-5 standards |

|

| Vitralit® 1655 | 150-300 (Brookfield LVT, 25 °C, Sp. 2/30 rpm) | epoxy |

UV secondary heat cure |

flexible certified to USP Class VI and ISO 10993-5 standards resistant to all common sterilization methods |

Bonding ABS SAN |

| Vitralit® 1722 | 5,000-8,000 (LVT, 25 °C, Sp. 4/30 rpm) | epoxy | UV |

Very high adhesion to most thermoplastics low shrinkage high temperature resistance |

Bonding thermoplastics Bonding FR4 or ABS suitable for bonding pretreated PET |

| Vitralit® 2025 | 200-400 | epoxy | UV |

Dry surface after UV-curing scratch-resistant transparent very high chemical and thermal resistance |

|

| Vitralit® 2028 | 160-300 | epoxy |

UV secondary heat cure |

Dry surface after UV-curing autoclavable excellent chemical resistance scratch resistant coating |

|

| Vitralit® 4730 | 70-150 | acrylate |

UV VIS |

Capillary flow flexible and tear-proof adhesive suitable for potting dry surface |

Bonding PC (Polycarbonate) hard-PVC, PET, ABS, SAN PMMA (Plexiglas®, acrylic glass) Joining glass and plastics Joining metals to plastics |

| Vitralit® 4735 HC | 700-1,000 | acrylate |

UV VIS secondary heat cure |

Very high adhesion to many plastics dry surface after curing flexible and tear-proof suitable for potting |

Bonding PC, PMMA (Plexiglas®, acrylic glass), hard-PVC, PET, ABS, SAN Joining glass and plastics Joining metals to plastics |

| Vitralit® 6008 VLV | 40-90 | acrylate |

UV VIS |

Capillary flow transparent tack-free surface |

|

| Vitralit® 6300 | 2,500-4,000 | acrylate |

UV VIS secondary heat cure |

jetable non-yellowing very high adhesion to glass and metals dual cure |

|

| Vitralit® 7256 | 600-1,000 | acrylate |

UV |

Non-yellowing transparent |

|

| Vitralit® 7561 | 500-900 | acrylate |

UV VIS |

Elastic low water absorption perfect solution for bonding large surfaces high resistance to moisture |

|

| Vitralit® 7631 | 100-300 | acrylate |

UV VIS |

Very high shear strength and bond strength excellent adhesion to plastics capillary flow behavior |

Bonding PMMA (Plexiglas®, acrylic glass), PC, PVC |

| Vitralit® 7641 | 10-100 | acrylate |

UV VIS |

Specially formulated for bonding PMMA high adhesion capillary flow |

Bonding PMMA (Plexiglas®, acrylic glass), PC, PVC |

| Vitralit® 7642 | 1,500-2,500 | acrylate |

UV VIS |

Excellent adhesion to many plastics high bond strength excellent flow properties |

Bonding PMMA (Plexiglas®, acrylic glass), PC, PVC |

| Vitralit® 9140 VL | 1,000-2,000 | acrylate |

UV VIS |

Flexible high resistance to moisture cures thick layers of adhesive |

Bonding PMMA (Plexiglas®, acrylic glass), PC, PVC, ABS |

| Vitralit® UV 2725 | 200-400 (LVT 25°C, Sp. 2/30 rpm) | acrylate |

UV VIS |

High peel strength flexible optically clear for bonding large surfaces |

*UV = 320 - 390 nm VIS = 405 nm