Photovoltaics and OPV

Organic photovoltaics (OPV) are creating radically new applications in consumer electronics. They include indoor light harvesting to extend battery life of wearables, and outdoor energy generation with performance previously unimaginable from conventional photovoltaics. The same is true for flexible electronics. Manufacturers are redefining the boundaries of volumetric form factor, functionality, and design flexibility in consumer and automotive electronics.

A critical contributor to these technology advancements has come from the advancement of bonding technologies. Adhesives now go beyond the basic benefits of sound structural bonding and provide additional functionality to the assembly. Working in conjunction with partners and customers, Panacol has successfully developed a range of multi-functional adhesive selections for applications in OPV and flexible electronics. For OPV applications, these adhesives provide higher resistance to environmental stresses. Adhesives for barrier foil lamination optimize the critical interplay between the pretreatment, foil, stack, and adhesive. New conductive adhesives efficiently adhere and protect electrical connections for SMD components in flexible packaging.

In all cases, the specific requirements of the application and its assembly process are key factors to consider when making an adhesive selection. Significant benefits can be realized when an optimal pairing is achieved with the component design, assembly, (UV) adhesive properties, and the curing process. Component and process design is afforded much greater flexibility. High throughput processes, including reel-to-reel, can be run with greater efficiency which reduces total cost of operation. Finished products can also possess more functionality and durability.

As new designs are evolving rapidly, very little standardization exists in the manufacturing of OPV. To support this evolution, adhesives must be modified or developed to meet the customers’ unique OPV design, materials, and processes.

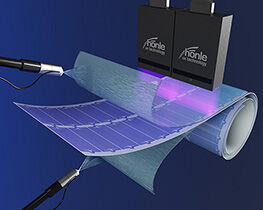

Adhesives are used for foil lamination on flexible photovoltaic cells

Download:

Video (lecture):

Lena Reinke at the Techblick Innovation Day 2024 on “Adhesive Solutions for Perokite-based and Organic Photovoltaic Applications”

In the following tables you will find a selection of Panacol adhesives suitable for OPV and photovoltaic assembly applications. Other products or customized solutions are available on request.

| Adhesive | Viscosity [mPas] | Base | Curing* | Properties |

|---|---|---|---|---|

| Vitralit® E-VBB-1 | 1,300 - 1,600 (Rheometer, 25 °C, 10s^-1) | acrylate | UV/VIS |

High peel strength; Optically clear; Outstanding flexibility; Excellent elongation; Resistant to moisture |

| Vitralit® UD 1410 | 1,500 - 2,000 (Rheometer, 25 °C, 10s^-1) | epoxy | UV/VIS/thermal |

Very good wetting properties Very flexible, low WVTR High Tg Electrically insulating |

| Vitralit® UH 1411 | 6,200 (Rheometer, 25 °C, 10s^-1) | hybrid | UV/VIS |

Very flexible, low WVTR (water vapour transmission rate) Flexible with approved compatibility to pv materials Very good wetting properties, electrically insulating |

| Elecolit® 3647-1 | n.n. | epoxy | thermal |

Very flexible, solvent-free Electrically conductive Thermally conductive Very high adhesion to glass, various metals and plastics |

| Elecolit® 3648 | 10,000 – 15,000 (Rheometer 10s^-1) | epoxy | thermal |

Very flexible, solvent-free Electrically conductive Thermally conductive Very high adhesion to glass, various metals and plastics Snap Cure Curing with thermode possible |

| Structalit® 3060-1 | 7,000-10,000 (Rheometer, 25 °C, 10^s-1) | epoxy | thermal |

non-conductive high flexibility very fast curing very low ion content high bond strength to several substrates |

*UV = 320 - 390 nm VIS = 405 nm

To download the technical datasheets (TDS) please click on the adhesive name.