Adhesives for E-Motor Assembly and Electric Vehicles

For electric drives, performance, weight and space savings are key. This increases the demands on the materials in terms of mechanical, chemical and thermal resistance in order to ensure long-lasting operation. Adhesives meet these requirements, adhere to various metals, ferrites and copper coils and are suitable for a wide range of applications, such as bonding stator stacks, thread windings or commutator fuses, right through to potting bar magnets.

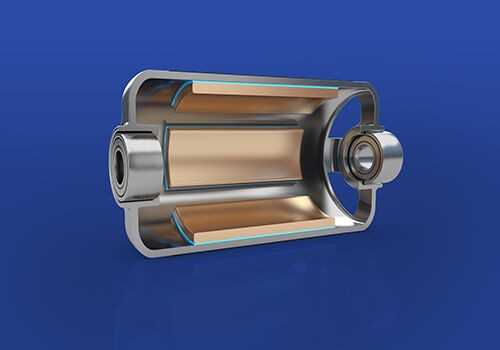

The adhesive marked in light blue shows exemplary bonding on an electric motor.

Magnet Bonding

Adhesives are the perfect solution for bonding magnets, as modern adhesives not only optimize the joining of housings and magnets, but can also protect and insulate the coil windings.

Adhesives with high adhesion to metals are required for these applications. Since metals are not permeable to UV light, Panacol offers dual-curing adhesives in addition to thermal cure products. These dual cure adhesives cure primarily by UV light, with a secondary anaerobic or moist curing mechanism for shaded areas.

The magnets in an electric motor are fixed with dual-curing adhesive

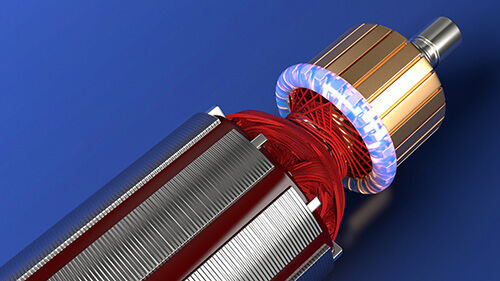

Commutator Securing with UV Adhesives

Panacol has developed special adhesives for securing wires to commutators that are extremely impact-resistant and cure quickly under UV light, making oven processes superfluous. These adhesives are highly viscous and stable, but at the same time flow into cavities thanks to optimized flow properties. The adhesive can be applied in a ring around the commutator in automated processes.

Commutators can be bonded quickly and reliably with UV adhesive

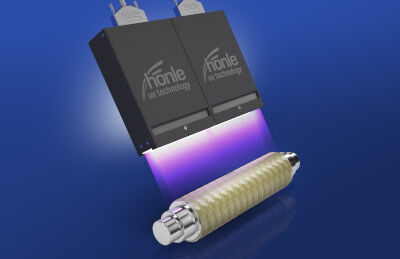

Filament Winding

Specially formulated adhesives are available for filament winding applications or for wrapping components such as hybrid rotor shafts for electric motors and high-voltage arresters. These adhesives are designed for materials such as CFRP (carbon fiber reinforced polymer) or GFRP (glass fiber reinforced polymer).

Filament winding process can be realized quickly and easily with UV adhesives

Panacol offers a wide range of fast curing adhesive technologies that have unique properties to better meet the challenges of electric motor assembly. Adhesive properties include a wide range of elongation values, high Tg values for reduced movement and improved elasticity to meet the operational requirements of the stator, rotor and magnets under high temperatures, shock and vibration. The Panacol adhesive portfolio is broad and includes 1- and 2-component epoxy resin adhesives as well as UV-, light- and dual-curing adhesives. They are particularly suitable for the various assembly and coating applications associated with the assembly of electric motors.

Download:

In the following table you will find a selection of adhesives suitable for the assembly of electric motors. More products and customer-specific solutions are available on request.

Technical data sheets can be downloaded by clicking on the adhesive name.

| Adhesive | Specific Application | Viscosity [mPas] | Base | Curing* | Properties |

|---|---|---|---|---|---|

| Vitralit® UD 1405 | Filament winding | 250-450 | epoxy |

UV VIS thermal |

Ideal for fiber-reinforced windings for electrical composite components Very good wetting properties Resistant to temperature Electrically insulating Transparent, one-component |

| Vitralit® UC 1406 | Filament winding | 250-450 | epoxy |

UV VIS |

Very good wetting properties Electrically insulating High glass transition temperature Solvent-free Ideal for filament winding |

| Vitralit® UV E-2113 | Securing commutators | 25,000-35,000 (Rheometer, 25°C, 10s^-1) | acrylate |

UV VIS |

Highly filled Low CTE Low shrinkage Impact resistant Dry surface Resistant to industrial soldering |

| Vitralit® 4282 mod2 | UV-anaerobic adhesive for flanges and ball bearings | 500-600 | acrylate |

UV secondary anaerobic |

UV curing thread locking fast anaerobic post-curing light green color |

| Vitralit® UD 4292 F | Bonding ball bearings of electric motors | 40-70 (LVT 25°C, Sp. 2/30 rpm) | acrylate |

UV VIS secondary anaerobic |

capillary flowing, bluish fluorescent, high Tg, secondary anaerobic curing |

| Structalit® 5803 | Magnet bonding | 100,000 mix (Rheometer, 25°C, 10s^-1) | 2-part epoxy | thermal, room temperature |

Black color Good oil, chemical and moisture resistance Impact resistant Low water absorption Very good adhesion to metal Flame classification based on UL 94 HB |

| Structalit® 5858 | Magnet bonding | 82,000-100,000 (Rheometer, 25 °C, 10s^-1) | epoxy | thermal |

Opaque, white color, adheres well to metal, impact resistant, good elongation at break |

| Structalit® 5859 | Adhesive for bonding magnets, flanges and ball bearings | 82,000-100,000 (Rheometer, 25 °C, 10s^-1) | epoxy | thermal |

Opaque, white color, adheres well to metal, impact resistant, good elongation at break |

| Structalit® 8801 |

Potting compound for electronic components Automotive: Magnet bonding |

30,000-45,000 (LVT, 25°C, Sp. 4/6 rpm) | epoxy | thermal |

Resistant to oils, grease and fuels excellent flow properties beige color certified to ISO 10993-5 standards |

| Structalit® 8838 | Potting ferrite cores, automotive switches | 6,500-7,500 (Rheometer, 25°C, 20s^-1) | epoxy | thermal |

Black color flexible potting compound excellent flow properties |

*UV = 320 - 390 nm VIS = 405 nm