Medical Grade Adhesive

Medical devices present manufacturers with a special challenge: As well as being health-compatible, the materials used must allow high-precision production and permanent joining and must withstand various sterilization methods. This applies especially to the adhesives used for assembly.

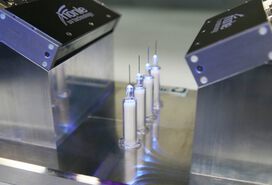

Medical grade adhesive can be used to bond medical products, such as syringes, dialysis filters, blood bags and tube connections. These medical products are usually made from a range of synthetic materials, including plastics that are hard to bond, such as PEEK, PE and PP. Common plastics such as PVC and ABS, on the other hand, are well suited to bonding.

Disposable medical products are often produced in large quantities. In addition to their mechanical bond strength, rapid curing of the adhesives used is important to allow high volume production. For transparent and UV-permeable materials, UV-curing medical grade adhesive can be used. For UV-impermeable substrates we recommend LED curing. For visual quality inspection, fluorescent versions of our medical grade adhesives are also available.

For reusable medical products, durability and the ability to withstand frequent sterilization play a vital role. Cured acrylate adhesives have a high resistance to sterilization by autoclaving, gamma radiation and ETO. These methods have no measurable negative impact on Panacol's medical grade adhesives. Electron-beam sterilization has even been shown to improve the adhesion of some medical grade adhesives of the Vitralit® series. This is due to an increase in the degree of polymerization of these products.

Typical applications of adhesives in medical device assembly are:

Specially formulated medical grade adhesives are certified for medical applications

Download:

Read more:

Lighting the Way to a Quicker Cure (pdf)

in: "Medical Device Developments", Spring 2015

Stick with it (pdf)

in: "Medical Plastics News", Sept/Oct 2014

The table below provides an overview of medical grade adhesives that are certified to ISO 10993 and/or USP Class VI and therefore suitable for medical applications:

| Medical grade adhesive | Application for medical grade adhesives | Viscosity [mPas] | Base | Curing* | Properties/ Certification |

|---|---|---|---|---|---|

| Structalit® 701 |

bonding surgical instruments endoscopes light guides |

3,000-5,000 | 2-part epoxy | thermal |

Transparent in thin layers long potlife fast curing certified to USP Class VI and ISO 10993-5 standards |

| Structalit® 5893 |

needle bonding plastic bonding |

6,000-10,000 (Rheometer, 25°C, 10s^-1) | epoxy | thermal |

Black color excellent flow properties filling material for frame&fill applications high resistance to heat and chemicals certified to ISO 10993-5 standards |

| Structalit® 8801 |

Potting compound for electronic components Automotive: Magnet bonding |

30,000-45,000 (LVT, 25°C, Sp. 4/6 rpm) | epoxy | thermal |

Resistant to oils, grease and fuels excellent flow properties beige color certified to ISO 10993-5 standards |

| Vitralit® 1605 |

optical cement lens bonding cement glass bonding medical device bonding |

200-400 (LVT, 25°C, Sp. 2/30 rpm) | epoxy |

UV secondary heat cure |

low shrinkage low heat expansion very high tg excellent chemical resistance certified to ISO 10993-5 standards |

| Vitralit® 1605 MV |

optical cement lens bonding cement glass bonding bonding of medical devices |

3,500-7,000 (Rheometer, 25 °C, 10s^-1) | epoxy |

UV secondary heat cure |

transparent, low shrinkage low heat expansion very high tg excellent chemical resistance certified to ISO 10993-5 standards |

| Vitralit® 1655 |

Medical devices bonding Flexible potting Optics |

150-300 (Brookfield LVT, 25 °C, Sp. 2/30 rpm) | epoxy |

UV secondary heat cure |

flexible certified to USP Class VI and ISO 10993-5 standards resistant to all common sterilization methods |

| Vitralit® 1702 |

Hose connections, blood filters |

10-100 | acrylate | UV |

Transparent capillary flow biocompatible: certified to USP Class VI standards |

| Vitralit® 1703 |

Hose connections, blood filters |

85,000-130,000 (LVT, 25 °C, Sp. 4/3 rpm) | acrylate | UV |

Shear thinning Shape retaining Certified according to USP Class VI Resistant to sterilization |

| Vitralit® 4731 |

Bonding hose fittings, bonding housings |

900-1,500 (LVT, 25°C, Sp. 3/30 rpm) | acrylate |

UV VIS |

Dry surface after curing, biocompatible: certified to USP Class VI and ISO 10993-5 standards |

| Vitralit® E-4731 |

Bonding hose fittings, bonding housings |

700-1,400 (LVT, 25°C, Sp. 3/30 rpm) | acrylate |

UV VIS |

Flexible, excellent adhesion to glass and plastics, dry surface, biocompatible: certified to USP Class VI and ISO 10993-5 standards, CMR-free |

| Vitralit® 5140 |

Sealing electrical assemblies, breathing masks |

250-500 | acrylate |

UV VIS |

Flexible, well suited for bonding plastics with low UV translucence and permeable to visible light, biocompatible: certified to USP Class VI standards |

| Vitralit® 6108 |

needle bonding bonding glass apparatus |

600-900 | acrylate |

UV VIS secondary heat cure |

non-yellowing excellent flow properties certified to USP Class VI and ISO 10933-5 standards |

| Vitralit® 6108 T |

needle bonding bonding glass apparatus |

3,000-6,000 | acrylate |

UV VIS secondary heat cure |

non-yellowing excellent gap-filling certified to USP Class VI standards shear thinning |

| Vitralit® 7041 |

Needle bonding, bonding enclosures |

50-90 (LVT 25°C, Sp. 2/60 rpm) | acrylate |

UV VIS |

Excellent adhesion to glass, plastics and metals; biocompatible: certified to USP Class VI standards |

| Vitralit® 7041 F |

Needle bonding, bonding enclosures |

50-90 | acrylate |

UV VIS |

Fluorescing, excellent adhesion to glass, plastics and metals; biocompatible: certified to USP Class VI and ISO 10993/-4/-5 standards |

| Vitralit® 7041 T |

Needle bonding, bonding dialysis filters |

1,500-2,300 | acrylate |

UV VIS |

High viscosity/stable, excellent adhesion to glass, plastics and metals; biocompatible: certified to USP Class VI and ISO 10993/-4/-5 standards |

| Vitralit® 7090 VHS |

Bonding catheters, needle bonding |

40-100 | acrylate |

UV VIS |

Dry surface, very high adhesion to plastics, biocompatible: certified to USP Class VI standards |

| Vitralit® 7311 FO |

Plastic bonding, glass bonding Suitable for large area bonding Suitable for applications with small gaps |

40-70 (Newtonian liquid, Rheometer, 25 °C) | acrylate |

UV VIS |

Fluorescing orange Capillary flowing Resistant to moisture and alcohol Biocompatible, certified according to USP Class VI and ISO 10993-5/10 Resistant to sterilization |

| Vitralit® 7311 FO T |

bonding plastics/glass bonding suitable for elastic bonding of large surfaces |

1,000-3,000 (Rheometer, 25 °C, 10s^-1) | acrylate |

UV VIS |

Fluorescing orange High resistance to alcohols and moisture non-yellowing very high adhesion to plastics, glass and metals suitable for bonding large areas certified according to USP Class VI |

| Vitralit® 7311 FO Gel |

plastics /glass bonding suitable for elastic bonding of large surfaces bonding of medical disposables |

18,000-35,000 (Rheometer, 25 °C, 10s^-1) | acrylate |

UV VIS |

Fluorescing orange, shape retaining Resistant to humidity and alcohol Certified according to USP Class VI Resistant to sterilization |

| Vitralit® 7989 |

Plastic bonding, bonding containers |

3,000-5,000 | acrylate | UV |

Excellent adhesion to plastics, especially to PC and PMMA; biocompatible: certified to USP Class VI standards |

| Vitralit® UV 4050 |

needle bonding plastic bonding |

140-500 (LVT, 25°C, Sp. 2/30 rpm) | acrylate |

UV VIS |

Certified to ISO 10993-5 and USP Class VI standards modified acrylate impact resistant very fast curing very high adhesion to plastics |

| Vitralit® UV 7030 | 15,000-25,000 (Rheometer, 25 °C, 10s^-1) | acrylate |

UV VIS |

Flexible, high elongation at break, very high shear strength, certified according to USP Class VI |

|

| Cyanolit® 203 TX |

Bonding hose unions, bridging large gaps, suitable for porous materials |

shear thinning | cyanoacrylate |

moisture, room temperature |

Biocompatible: certified to USP Class VI standards |

| Cyanolit® 241 F |

Plastic bonding, metal bonding |

30-50 | cyanoacrylate |

moisture, room temperature |

Capillary flow, biocompatible: certified to USP Class VI standards |

| Cyanolit® 290 WR | 400 (LVT, 25 °C, Sp. 2/60 rpm) | cyanoacrylate |

athmospheric moisture room temperature |

Instant adhesive, fast-curing, water-resistant, chemical-resistant, moisture-resistant, certified to ISO 10993-5 | |

| Cyanolit® 732 F |

Bonding coloured plastics, delicate bonds |

230-350 (LVT, 25 °C, Sp. 2/60 rpm) | cyanoacrylate |

moisture, room temperature |

Film forming, suitable for bonding porous materials, biocompatible: certified to USP Class VI standards |

| Elecolit® 323 | Bonding of EP catheters | paste-like | 2 component epoxy | thermal |

electrically conductive (ICA) thermally conductive ISO 10993-5/-12 certified |

*UV = 320 - 390 nm VIS = 405 nm