Epoxy adhesives

Epoxy resin-based adhesives have many uses in industrial applications. They generally consist of resin and hardening agents. Curing epoxy adhesives can take place either at room or elevated temperature, or through photoinitiators and UV light. Modern photoinitiators also react to the special UV spectrum of LED light sources, so that newly developed epoxide resin adhesives can be cured with both UV and UV LED light.

The benefits of epoxy adhesives are:

- Good resilience against environmental and media influences

- Epoxies can be used at higher temperatures

- Epoxy adhesives feature high glass transition temperatures

- Cured epoxy adhesives usually have dry, non-tacky surfaces, making them suitable also as one-sided protective coatings

- Some epoxies exhibit very good optical properties and diffraction indexes, making them useful for applications in precision optics, lens bonding and information technology

- The epoxide ring created in the cross-linking reaction significantly reduces shrinkage

- Epoxy adhesives have an extremely low ionic content and low alkaline and halogen content, down to less than 10 ppm

- Epoxy adhesives offer a wide range of different material characteristics: from flexible and soft with high elongation at break to hard and scratch-resistant with extremely high bond strength

Panacol offers four different ranges of epoxy resin adhesives:

- The Structalit® series comprises a range of thermally curing one- and two-component adhesives

- The conductive adhesives of the Elecolit® series are also mostly heat-curing

- The epoxy adhesives of the Vitralit® series cure under UV or UV LED light

- The Optocast and Emcast adhesives of US manufacturer EMI

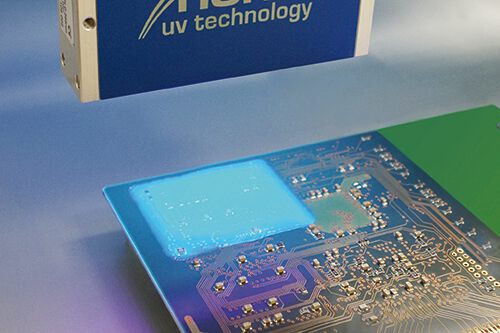

A fluorescent epoxy resin is being applied as conformal coating on a circuit board and cured with UV LED light