Attaching Components on PCBs

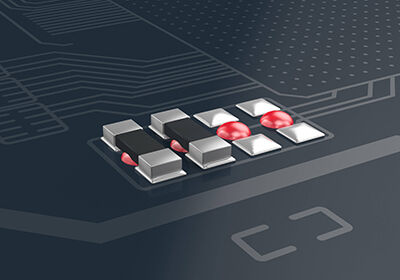

Before soldering processes, chips or SMDs (surface mounted devices) are often attached to the PCB (printed circuit board) with UV-curing adhesive. This allows, for example, several chips or other components to be glued onto on a circuit board within just a few seconds to prevent their falling or sliding out of position on the PCB. The secured chips can then be reflow-soldered in a single work step, which saves time and speeds up production.

Panacol’s adhesives for SMD assembly have been developed specially to cure rapidly at exposure to heat or under UV light. Once cured, the adhesives in the table below are short-term temperature-resistant and therefore suitable for holding components before and during reflow soldering onto PCBs.

On request these adhesives are also available with red or fluorescent pigment to facilitate quality and application monitoring. Their red color or fluorescence makes the adhesive clearly visible to allow the bond quality of every component to be easily inspected also in mass production. Especially the red color creates a clear contrast to the usually green PCBs.

Adhesives secure components on PCBs

The table below lists a selection of Panacol adhesives that are suitable for holding components on PCBs and for reflow soldering. Further products and custom solutions are available on request.

To download the technical datasheets (TDS) please click on the adhesive name.

| Adhesive | Viscosity [mPas] | Base | Curing* | Properties |

|---|---|---|---|---|

| Vitralit® UD 2018 | 11,000-25,000 (Rheometer, 25°C, 10s^-1) | epoxy |

UV secondary heat cure |

Resistant to temperature cycles low shrinkage low thermal expansion coefficient red color pink fluorescent |

| Vitralit® UV 2115 | 20,000-30,000 (Rheometer, 25°C, 50s^-1) | acrylate |

UV VIS |

Acrylate hybrid superior strength low thermal expansion low shrinkage impact resistant resistant to soldering stress paste-like stable and high viscous |

| Structalit® 3060-1 | 7,000-10,000 (Rheometer, 25 °C, 10^s-1) | epoxy | thermal |

non-conductive high flexibility very fast curing very low ion content high bond strength to several substrates |

| Structalit® 5604 | 25,000-40,000 (Rheometer, 25 °C, 10s^-1) | epoxy | thermal |

Fast curing red color fixing components on PCBs SMD applications |

| Structalit® 5606 F | 22 000 - 30 000 (LVT, Sp. 4/6 rpm) | Epoxy | Thermal |

1part epoxy, fluorescing bluish Fast curing at low temperatures High shock resistance Short time resistant to soldering temperatures up to 270° C |

| Structalit® 5705 | 7,000-12,000 | epoxy |

thermal |

Black color, yellow fluorescent, reworkable above 150°C, jettable, low in halogens, very suitable as edge bonding adhesive |

| Vitralit® 6104 VT | 8,000-17,000 (Rheometer, 25°C, 10s^-1) | acrylate |

UV secondary heat cure |

Very high adhesion to metals and sintered materials ideal for bonding large components on circuit boards (corner bonding) |

| Vitralit® UD 8055 | 5,000-8,000 (Rheometer, 25°C, 10s^-1) | acrylate |

UV VIS moisture cure |

High Tg Fast curing Compatible with flux Low ion content |

| Vitralit® UD 8056 | 3,000-6,000 (Rheometer, 25°C, 10s^-1) | acrylate | UV / VIS / Moisture postcuring |

High Tg, fast curing Compatible with flux Low ion content Passed UL94 HB test |

*UV = 320 - 390 nm VIS = 405 nm