Needle Bonding

A main field of application for adhesives in medical systems is needle bonding and syringe assembly – the bonding of stainless steel needles or cannulas into glass or plastic syringes. The needles’ required high withdrawal forces are achieved through precision manufacture (needle position, adhesive dosing and reliable adhesive curing), choice of hub (material and design) and, in particular, the right adhesive system.

Already the hub material used affects the choice of adhesive, since not all adhesives adhere well to all plastics. Many adhesives are UV-curing, which requires the use of transparent and UV-permeable materials. For materials that block UV light, such as polycarbonates, long-wave LED curing is recommended. All needle bonding adhesives listed in the table below can be LED-cured.

The hub design also plays an important role for the assembly of syringes: it determines whether a mobile adhesive that flows into the needle hub through capillary action or a highly viscous adhesive capable of filling large gaps is used. In some cases the needle shaft must be designed with grooves to provide an additional key for the adhesive.

Panacol offers various adhesives that are suitable for bonding stainless steel needles into glass syringes and stainless steel cannulas into syringes made from plastics such as PC, PVC, PP or ABS. All adhesives recommended for needle bonding are solvent-free and certified USP Class IV and/or ISO 10993 for use in medical equipment. In addition, high needle extraction forces were measured with all needle bonding adhesives even after several sterilization cycles. Electron-beam sterilization has even been shown to improve the adhesion of some adhesives of the Vitralit® series.

All adhesives are also available in fluorescent versions, which allows a fast and efficient quality control during production.

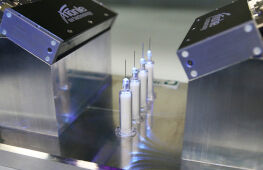

Needle bonding: A needle is being bonded into a syringe; the adhesive is cured with two LED heads

Download:

Video:

Smart system solution for needle bonding with bdtronic dispensing and Hönle uv curing equipment (pdf)

Video:

Needle bonding in an automated production line

The table below lists a selection of needle bonding adhesives from Panacol. Further products and custom solutions for needle assembly are available on request.

To download the technical datasheets (TDS) please click on the adhesive name.

| Adhesive/ Needle Bonder | Viscosity [mPas] | Base | Curing* | Properties |

|---|---|---|---|---|

| Vitralit® 6108 | 600-900 | acrylate |

UV VIS secondary heat cure |

non-yellowing excellent flow properties certified to USP Class VI and ISO 10933-5 standards |

| Vitralit® 6108 T | 3,000-6,000 | acrylate |

UV VIS secondary heat cure |

non-yellowing excellent gap-filling certified to USP Class VI standards shear thinning |

| Vitralit® 7041 | 50-90 (LVT 25°C, Sp. 2/60 rpm) | acrylate |

UV VIS |

Excellent adhesion to glass, plastics and metals; biocompatible: certified to USP Class VI standards |

| Vitralit® 7041 T | 1,500-2,300 | acrylate |

UV VIS |

High viscosity/stable, excellent adhesion to glass, plastics and metals; biocompatible: certified to USP Class VI and ISO 10993/-4/-5 standards |

| Vitralit® 7311 FO | 40-70 (Newtonian liquid, Rheometer, 25 °C) | acrylate |

UV VIS |

Fluorescing orange Capillary flowing Resistant to moisture and alcohol Biocompatible, certified according to USP Class VI and ISO 10993-5/10 Resistant to sterilization |

| Vitralit® UV 4050 | 140-500 (LVT, 25°C, Sp. 2/30 rpm) | acrylate |

UV VIS |

Certified to ISO 10993-5 and USP Class VI standards modified acrylate impact resistant very fast curing very high adhesion to plastics |

| Structalit® 5893 | 6,000-10,000 (Rheometer, 25°C, 10s^-1) | epoxy | thermal |

Black color excellent flow properties filling material for frame&fill applications high resistance to heat and chemicals certified to ISO 10993-5 standards |

*UV = 320 - 390 nm VIS = 405 nm