Glob Top Sealing Compounds

Sealing compounds and encapsulants are often used in electronics as so-called glob tops to protect electronic components. They protect components from moisture, dust, dirt and solvents. Glob tops also protect sensitive components from mechanical strain and scratching.

All Panacol sealing compounds and encapsulants are made without solvent and many have a low ionic content of less than 10 ppm Na+, K+, Cl- and Br-. They therefore provide perfect protection from internal corrosion and reduce local voltaic coupling.

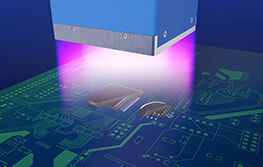

Many sealing compounds are UV-curing, allowing rapid setting in just a few seconds. This makes them suitable for encapsulating components in fully automated high-volume production.

Thermally curing sealing compounds, on the other hand, have the advantage of curing even in shaded areas that the UV light cannot reach. Glob tops with black pigmentation, which are used as covers or coatings, can normally only be heat-cured.

After curing, all Panacol glob top sealing compounds withstand short-term temperatures of up to 280°C and remain unaffected by reflow processes. Panacol’s glob top adhesives are easy to process, highly flexible and have a high peel and shear strength.

Glob tops protect components on FR4 boards.

"Black & Light" Adhesives

What is new is that many of our black adhesives can now also be cured with UV light in thick layers. This new Black&Light technology allows complete curing with UV light without resorting to secondary curing mechanisms. This technology is compatible with most of Panacol's epoxy-based Vitralit® adhesives. Depending on the application, the black coloration and layer thickness of the adhesives can be individually adjusted.

Another major advantage of the new "Black&Light" adhesives is storage: while conventional black-filled epoxy resin adhesives usually have to be stored deep-frozen, the "Black&Light" epoxy resins can be stored and shipped at room temperature or refrigerated, depending on the adhesive.

You can find more information on these adhesives on our "Black&Light" page.

Black epoxy adhesives are cured with the UV Spot 100 from Hönle

The table below lists a selection of sealing compounds suitable for glob tops. Further products and custom solutions are available on request.

To download the technical datasheets (TDS) please click on the adhesive name.

| Glob top | Application | Viscosity [mPas] | Base | Curing* | Properties |

|---|---|---|---|---|---|

| Vitralit® 1600 LV |

attaching components on PCBs conformal coating encapsulation of electronic components chip encapsulation potting material automotive, aerospace smart card |

3,000-5,000 | epoxy |

UV secondary heat cure |

Very high Tg low water absorption low ion content very high chemical resistance |

| Vitralit® 1650 |

glob top encapsulation conformal coating encapsulation of electronic components chip encapsulation potting material automotive, aerospace smart card |

3,000-5,000 | epoxy | UV |

Electronic grade low ion content suitable for chip protection UL94 HB test passed |

| Vitralit® 1671 |

glob top encapsulation conformal coating encapsulation of electronic components chip encapsulation potting material attaching components on PCBs SMD assembly display sealing smart card |

9,000-14,000 (Rheometer, 10s^-1) | epoxy |

UV secondary heat cure |

Stable frame compound high ion purity electronic grade adhesive high temperature conductivity low water absorption UL94 HB test passed |

| Vitralit® E-1671 |

glob top encapsulation conformal coating encapsulation of electronic components chip encapsulation potting material attaching components on PCBs SMD assembly |

9,000-14,000 (Rheometer, 10s^-1) | epoxy |

UV secondary heat cure |

Stable frame compound high ion purity electronic grade adhesive high temperature conductivity low water absorption |

| Vitralit® 1688 |

glob top encapsulation conformal coating encapsulation of electronic components chip encapsulation potting material smart card |

1,200-2,000 | epoxy | UV |

Excellent flow properties and leveling electronic grade adhesive low ion content suitable for chip protection excellent resistance to heat and humidity |

| Vitralit® 1691 | glob top encapsulation | 20,000-40,000 | epoxy |

UV secondary heat cure |

black color high ion purity electronic grade adhesive high temperature resistance fast surface curing with UV light |

| Vitralit® BL UC 1101 |

medical devices optics electronics lens bonding light shielding |

3,500-7,000 (Rheometer, 25 °C, 10s^-1) | epoxy | UV |

black colour low shrinkage low CTE high glass transition temperature good chemical resistance resistant to sterilization |

| Vitralit® BL UC 1102 |

medical devices optics electronics lens bonding light shielding |

3,500-7,000 (Rheometer, 25 °C, 10s^-1) | epoxy | UV |

black colour low shrinkage low CTE high glass transition temperature good chemical resistance resistant to sterilization |

| Vitralit® BL UC 1103 |

medical devices optics electronics lens bonding light shielding |

3,500-7,000 (Rheometer, 25 °C, 10s^-1) | epoxy | UV/VIS |

black colour low shrinkage low CTE high glass transition temperature good chemical resistance resistant to sterilization |

| Vitralit® UD 5180 |

glob top encapsulation attaching components on PCBs conformal coating encapsulation of electronic components SMD assembly plastic bonding potting material automotive, aerospace |

4,000-6,000 | epoxy |

UV secondary heat cure |

Perfect solution for bonding flexible circuit paths resistant to reflow processes grey color |

| Vitralit® UD 8050 |

Conformal Coatings Glob Top Encapsulants |

8,000-11,000 (Rheometer, 25 °C, 5s-1) | acrylate |

UV VIS secondary moisture cure |

Isocyanacrylate; fast moisture post-curing in shadowed areas; easy to dispense with jet or dispenser e.a.; resistant to moisture; compatible with flux |

| Vitralit® UD 8055 |

Protective encapsulation of electronic components on PCBs Consumer electronics |

5,000-8,000 (Rheometer, 25°C, 10s^-1) | acrylate |

UV VIS moisture cure |

High Tg Fast curing Compatible with flux Low ion content |

| Vitralit® UD 8056 |

Consumer Electronics Protective encapsulation of electronic components on PCBs |

3,000-6,000 (Rheometer, 25°C, 10s^-1) | acrylate | UV / VIS / Moisture postcuring |

High Tg, fast curing Compatible with flux Low ion content Passed UL94 HB test |

| Vitralit® UD 8057 |

Consumer Electronics Protective encapsulation of electronic components on PCBs |

2,000-4,000 (Rheometer, 25°C, 5s^-1) | acrylate | UV / VIS |

Highly transparent Resistant to yellowing High bond strength to several substrates |

| Structalit® 5717 |

Fill-material for "Frame&Fill" Glob top Electrics Electronics |

3,000-8,000 (Rheometer, 25°C, 10s^-1) | epoxy | thermal |

Black color, very good flowability High glass transition temperature No bleeding Very low ionic content (<10ppm) Suitable for semiconductors |

| Structalit® 5719 |

Fill-material for "Frame&Fill" Glob top Electrics Electronics |

7,000-11,000 (Rheometer, 25°C, 5s^-1) | epoxy | thermal |

Very good flowability High glass transition temperature No bleeding Very low ionic content (<10ppm) Suitable for semiconductors |

| Structalit® 5891 |

glob top encapsulation plastic bonding SMD assembly |

25,000-50,000 ( Rheometer, 25 °C, 10s-1 ) | epoxy | thermal |

Black color fast curing at low temperatures impact resistant |

| Structalit® 5891 T |

glob top encapsulation SMD assembly attaching components on PCBs |

80,000-150,000 (Rheometer, 25 °C, 10s^-1 ) | epoxy | thermal |

Black color stable frame material, can be applied wet-in-wet with filling material, suitable for frame stacking stable edges resistant to shocks |

| Structalit® 5893 |

glob top encapsulation SMD assembly medical technology needle bonding frame&fill |

6,000-10,000 (Rheometer, 25°C, 10s^-1) | epoxy | thermal |

Black color excellent flow properties filling material for frame&fill applications high resistance to heat and chemicals certified to ISO 10993-5 standards |

| Structalit® 5894 M |

glob top encapsulation encapsulation of electronic components SMD assembly automotive, aerospace potting material |

20,000-30,000 (Rheometer, 25 °C, 20s ^-1) | epoxy | thermal |

Black color excellent flow properties filling material for frame and fill applications on PCBs, very high resistance to heat and chemicals |

| Structalit® 8801 |

attaching components on PCBs encapsulation of electronic components SMD assembly encapsulation of plastic parts potting material automotive, aerospace |

30,000-45,000 (LVT, 25°C, Sp. 4/6 rpm) | epoxy | thermal |

Resistant to oils, grease and fuels excellent flow properties beige color certified to ISO 10993-5 standards |

| Structalit® 8838 |

attaching components on PCBs encapsulation of electronic components SMD assembly |

6,500-7,500 (Rheometer, 25°C, 20s^-1) | epoxy | thermal |

Black color flexible potting compound excellent flow properties |

*UV = 320 - 390 nm, VIS = 405 nm